Intamin Amusement Rides

SCHAAN

// REFERENCE RAIL

Pure thrills

Intamin Amusement Rides plans roller coasters with ProVI

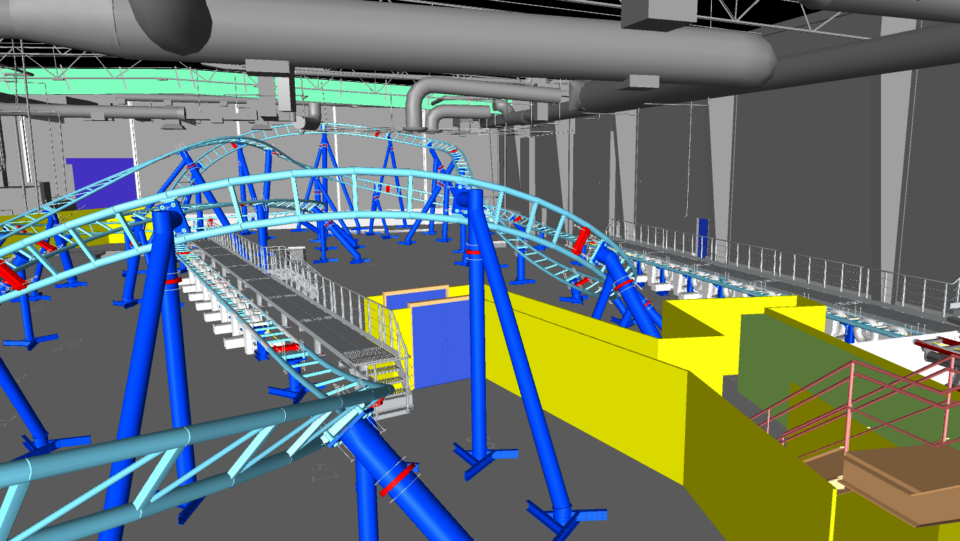

Intamin Amusement Rides is one of the leading and largest manufacturers of amusement rides worldwide. Founded in Switzerland in 1967, the family-owned company with around 150 employees develops, manages and produces all kinds of amusement rides such as roller coasters, free-fall towers, water rides and Ferris wheels. Intamin – short for International Amusement Installations – has built some of the world’s tallest, longest and fastest roller coasters and has already delivered more than 1,000 rides worldwide. Thanks to ProVI, Intamin has been able to simplify many of its planning and construction tasks, make processes more efficient and minimize potential sources of error.

The customer spectrum of the Swiss-Liechtenstein company group is broad: It ranges from individual amusement parks such as Phantasialand in Germany to large chains such as Universal, Disney, Seaworld or Busch Gardens to investors or investor groups who, for example, want to build shopping centers in Dubai or Abu Dhabi and integrate amusement facilities there.

A lucky coincidence

Intamin is satisfied ProVI customer for three years already. “Previously, we did the entire planning of a ride by hand: we created an unfolding, then drew a top view and derived the 3D model from it. If something changed somewhere, we had to adjust everything again by hand,” recalls Michael Bauert, Head of Ride System Engineering and already working at Intamin for ten years. He calls the fact that the company came into contact with ProVI a lucky coincidence. “At the time, we had an employee who got an introduction from me. I showed him how we work, how we lay out, position, and design the rigs, and also told him that I wasn’t entirely happy with the laborious manual process. He suggested that we could use ProVI for that.”

How to plan roller coasters with routing software

Since ProVI was developed for planning roads and tracks, Intamin only uses the software for roller coasters, not for free-fall towers or similar. A roller coaster is basically always the same in terms of its structure: it consists of a station area for entry and exit, a track on which energy is built up, for example a lift or an acceleration track, and finally again a brake in front of the station. Nowadays, however, roller coaster riders demand a bit more “action” and variety, as Michael Bauert describes: “A ‘normal’ roller coaster is almost boring today. Nowadays, a roller coaster has to have several acceleration tracks; moreover, the projects are usually characterized by a double station and several block brakes as well as a very dense ride profile of the trains for high capacity. This requires many fixtures in the rails, which can be quickly and reliably placed with ProVI and easily adjusted when changes are made. The larger and more complex the projects, the more we can benefit from ProVI.”

While there are only minimal inclines and cross slopes in road and rail design, roller coasters perform far more daring maneuvers such as 360-degree loops. For this reason, ProVI is only used for flat areas without cross slopes, such as in the station, or for braking sections. A lift with a constant incline can also be mapped with ProVI. Nevertheless, Intamin first had to test the possibilities and limits of the routing software in order to be able to apply the functions to the construction of a roller coaster. For the so-called “Gravity Run,” in which all three angles (orientation, longitudinal inclination and transverse inclination) change permanently, Intamin works with a German partner company.

From the white sheet of paper to the stomach tingling at the first loop

But how are roller coasters actually designed? It usually starts with a mix of the customer’s idea and Intamin’s ideas, says Bauert: “Individual customers usually come with an idea – they’d like a roller coaster with two acceleration sections and five inversions, for example. Then our design department starts designing. Large chains like Disney and Universal have very clear ideas and usually their own designers and programs. They almost come to us with a finished layout and then want fine-tuning for it.” It usually takes two to three years from kick-off to handover. During this time, Intamin has at least one project manager and one ride system engineer actively involved in the process of creating the ride. For larger installations, the project manager is supported by project assistants and other project engineers.

More efficient, faster, simpler

Projects implemented with ProVI are characterized above all by their high efficiency. “We just recently had two commissionings on projects that were implemented without ProVI. By the time we had compiled and reconciled all the data from design, engineering and manufacturing for our system checks (e.g. braking distances), it was quite an effort,” reports Michael Bauert. “In projects with ProVI, the data basis is completely different. We have all the data in a uniform format in the database, can read it out, verify it directly and, what’s more, change management is extremely simple.” Database-driven design enables a systematic way of working, and adjustments that often arise from customer requests take much less time. Another advantage of the software, according to the Head of Ride System Engineering, is the ability to quickly create initial layouts in 3D.

Long-time colleagues in particular, who still remember the manual way of working, are very positive about the software. “The ride system engineer can now concentrate more on his core task, ‘engineering’, and less on the correct representation of the top view, unwinding and 3D display. We can now spend more time on designing a system better in terms of energy as well, so that, for example, the number of motors for propulsion can be reduced to optimize energy consumption,” Michael Bauert continues.

Successful cooperation

The engineer rates the cooperation with ProVI as very good. “In response to our nevertheless very specific and special inquiries about how to solve our problems with ProVI, the training and support level organized its own training. In it, we learned how to make the most of the new ProVI 7.0 version and create BIM-capable models. Also, the response times are fast and the support is at a high level.”

Looking to the future, Bauert sees the biggest advantage in ProVI’s BIM capability, “We see the growing need of customers who work a lot with Revit and Navisworks. Certain customers also use a BIM platform, to which we also need to upload our model. ProVI gives us the ability to do that because 3D models can be exported as IFC files.”

The larger and more complex the projects, the more we can benefit from ProVI.

Michael Bauert, Head of Ride System Engineering, Intamin Amusement Rides

We have all the data in a uniform format in the database, can read it out, verify it directly and, what’s more, change management is extremely simple.

Michael Bauert, Head of Ride System Engineering, Intamin Amusement Rides